|

|

Post by Rock Dawg on Nov 10, 2009 17:20:42 GMT -5

Cousinmikes build thread for his jeep racer.  What a way to start :-)..     Adding room to the body  Adding more length and more wheel well  Comp cutting baby!!  Have the axles under it. |

|

|

|

Post by chevtech on Nov 10, 2009 20:02:47 GMT -5

Great start and progressing nicely, the frame shortening and body stretching looks good.

|

|

|

|

Post by WILLYNILLY on Nov 10, 2009 20:25:35 GMT -5

good work! cant wait to see how it comes out!

|

|

|

|

Post by The Black Jeep on Nov 10, 2009 22:43:08 GMT -5

WOW, talk about starting from scratch  |

|

|

|

Post by mudslinger97117 on Nov 12, 2009 0:04:55 GMT -5

so it's an early cj?Pre 1950? running a smallblock? details rusty c'mon... looking good. keep up the work

|

|

|

|

Post by Rock Dawg on Nov 12, 2009 11:49:33 GMT -5

This is my Cousin's build thread AKA "cousinMike".. He went to watch some "Barrel racing" this summer and got bit by the bug. So he is starting to build one :-). I just started the build thread for him so we could keep track of his progress and help when he needs it. I think he is planning on building the tub to be easily removable, and I know how he drives (He will roll it  ), so building the roll cage will have to be strong and removable as well. Oh, buy the way... He go a sweet new power plant for it this weekend. I won't give it away, (that is for him to tell) but It will be fast once completed :-) |

|

|

|

Post by cousinmike on Nov 16, 2009 0:58:25 GMT -5

OK OK I guess I better clear the air. So far the project has taken on three rigs.  It all started with the 1947 Willys jeep, but the problems were there wasn't enough power and not big enough. I like the room my TJ has. The 14" stretch made the tub about the same length as the TJ tub. And the Willys is only 1-1/2" narrower that the TJ, so I decided to leave the body width alone. To accomodate the stretched body I used a 74 J20 pickup and removed 42" from the frame  . The wheelbase went from 130" to 94". (I'm ok with math 8-)130-42=88  I turned the rear springs around as the alxe pin is offset) I started taking pics of the build after I started hacking.  I was planning on building the stock 360, but I had a voice in my head I couldn't get rid of. So out it came.    Pressure washed the frame and ready for prep and paint.  Even though I drive a Ford, I really am a Chevy guy. So here's where the power's coming from.  Chevy 350/Th350/NP205   |

|

|

|

Post by cousinmike on Nov 24, 2009 14:43:54 GMT -5

Got the frame cleaned up and painted last week. This weekend I got the drive train out of the pickup and into the jeep. Had to fab my own motor and t-case mounts. Now it's starting to take shape. put the tub back on last night, now i have to start re-constructing the floor boards and frame mounts.

Also thanks for the roll bar advise. I should bend tubing next week. got a guy trading the wheels and tires from the Willy's for the tubing.

I'll get some updated pic's when I can.

|

|

|

|

Post by mudslinger97117 on Nov 24, 2009 20:06:07 GMT -5

looking good mike, you still have your tj right?

|

|

|

|

Post by cousinmike on Nov 24, 2009 21:08:34 GMT -5

Ya, it's turned into my wifes dd. I think she likes the attention especially with the Poorboyoffroad on the windshield even though she wont admit it. LOL

I plan on keeping it so I have something street legal since the flatty wont be at least for a while.

|

|

|

|

Post by cousinmike on Nov 25, 2009 1:10:12 GMT -5

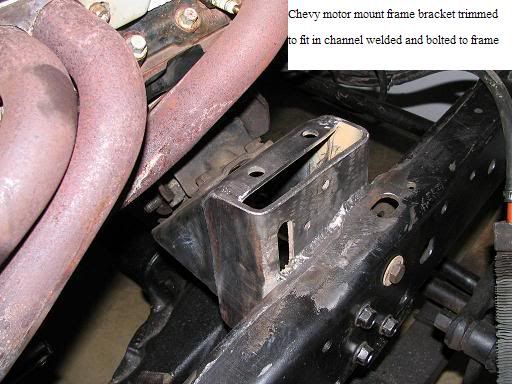

Here's the motor mounts. After a few cups of coffee and half a day of scratching some more hair of my head this is what came out. I clamped a piece of channel to the frame then, keeping the frame mounts from the Chevy pickup, positioned the motor into the channel, welded it into place and bolted the channel to the frame. Now the motor sits about three inches further back due to the motor mount locations between the Jeep and Chevy blocks.   The T-case cross-member from the Chevy pickup was used here. This is the type that bolts to the bottom of the frame. With the motor mounted and top of the intake level I had to cut the cross-member and weld it to another channel section and bolt it to the frame. This worked out really slick as both the motor mounts and cross-member were bolted in the same location as the stock jeep mounts.   When I positioned the body with the Jeep motor I ended up with a foot of frame sticking out from the rear of the body. Now with the motor set back more the frame only sticks out 8 inches. This is due to the 56 inch rear springs.  |

|

|

|

Post by WILLYNILLY on Nov 25, 2009 8:57:13 GMT -5

Lookin good!

|

|

|

|

Post by Rock Dawg on Nov 28, 2009 22:59:33 GMT -5

Sweet! It look light and fast with the missing floorboards in it ;-)..

|

|

|

|

Post by BIG chief on Nov 28, 2009 23:31:17 GMT -5

Sweet! It look light and fast with the missing floorboards in it ;-).. thats so his brakes work YABBA DABBA DOOOOOO |

|

|

|

Post by cousinmike on Nov 29, 2009 11:22:34 GMT -5

I'm waiting for some more materials from a friend and contemplating buying a tubing bender before starting the floor. You can see the benders I'm considering here poorboy1.proboards.com/index.cgi?board=4x4&action=display&thread=7759I think I'm going to weld the cage to the frame and flange it at the floor boards. This will also work as the body mounts. |

|