Post by cousinmike on Feb 28, 2012 23:54:41 GMT -5

Here's the problems my tranny had and parts I replaced due to either just being warn or just upgraded.

Here's the band. This applies to the direct drum only when in 2nd gear manually. The liner completely came apart one the band that was in my tranny. That's why my jeep felt like it was coasting when under deceleration in manual 2nd gear.

This is the direct drum that the band runs on. The sprag gear here was replaced with a hardened gear. This is one of the weakest parts in these trannys. The gear runs on a one way roller bearing. You can see grooves that wore in inside where the pump stator seals ride. The grooves do not allow the seals to hold like they should and channel the fluid to the clutch packs.

Here's the intermediate and low reverse roller clutches. These are recommended to be replaced as the accordion springs get weak and the cage gets warn.

Here's the other side of the direct drum. This is the bushing that gets the most wear. You can see the scoring.

Here's the pump stator I replaced. This is an old style. The newer style has another groove for a nylon seal to help stabilize the front of the direct drum which help with the direct drum bushing life. Also, the newer stators have a polished sleeve that can be replaced where this one is machined into the stator.

Here's the pump gears. There should only be about 0.0015" clearance between the pump gear and case. My pump was out of tolerance so I replaced it with a newer remanufactured style pump. The trannny shop said that I was picky and the main thing to worry about is the there are sharp edges in the pump housing and the side gear clearance wasn't as much of an issue. But I want to make sure the pressures are where they should be.

New pump installed

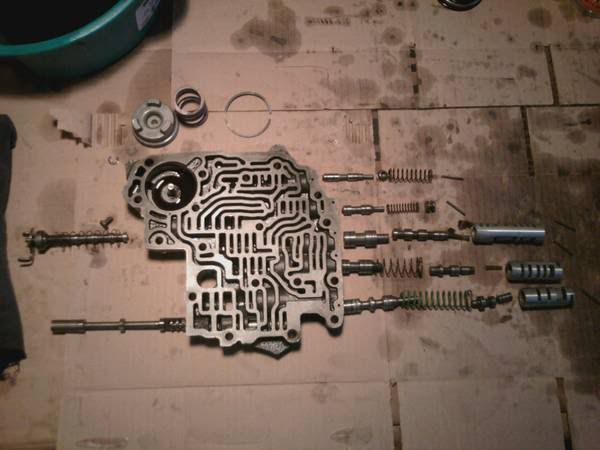

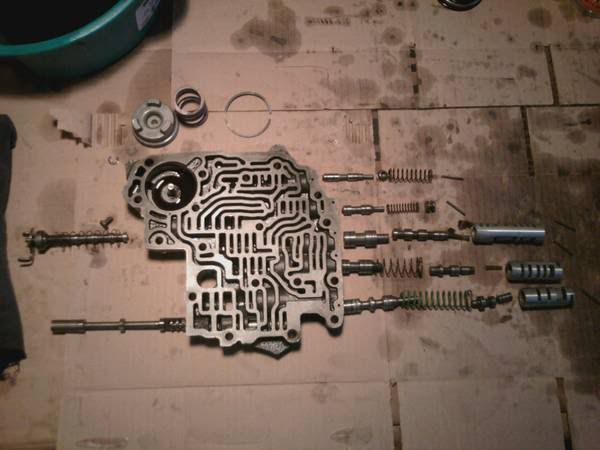

Exploded view of the valve body. I put a stage three shift kit in. They say cleanliness and staying organized is the main thing to worry about here. DO NOT WISE DOWN WITH RAGS OR PAPER TOWELS. The valves have very tight tolerance and can easily get hung up by a piece off lint or debris.

Valve body gasket on and ready for the intermediate servo piston and valve body. Again parts organization is a must. The two studs sticking out where the valve body goes are tow 5/16" bolts 2-1/2" long with the heads cut off and slotted for a flat head screw driver. these help line up the gaskets and valve body. The studs are also used when installing the pump assembly.

Valve body installed.

Remember I said keep parts organized? Well after installing the valve body I noticed this washer on the bench. Luckily I remembered it goes between the intermediate servo piston and apply pin. Oops, off with the valve body, install washer, reinstall valve body.

Little trick in knowing if your tork converter is in all the way. With a flat edge across the bolt flange measure to the converter lug flanges. This should be about 1 inch. I replaced my stock converter with a 2600 stall.

Tranny all together

Two 3/8" studs to help line up the tranny for the install.

I also used red high performance clutches. new steels, seals, gaskets, all new bushings, thrust washers and torrington bearings.

Here's the band. This applies to the direct drum only when in 2nd gear manually. The liner completely came apart one the band that was in my tranny. That's why my jeep felt like it was coasting when under deceleration in manual 2nd gear.

This is the direct drum that the band runs on. The sprag gear here was replaced with a hardened gear. This is one of the weakest parts in these trannys. The gear runs on a one way roller bearing. You can see grooves that wore in inside where the pump stator seals ride. The grooves do not allow the seals to hold like they should and channel the fluid to the clutch packs.

Here's the intermediate and low reverse roller clutches. These are recommended to be replaced as the accordion springs get weak and the cage gets warn.

Here's the other side of the direct drum. This is the bushing that gets the most wear. You can see the scoring.

Here's the pump stator I replaced. This is an old style. The newer style has another groove for a nylon seal to help stabilize the front of the direct drum which help with the direct drum bushing life. Also, the newer stators have a polished sleeve that can be replaced where this one is machined into the stator.

Here's the pump gears. There should only be about 0.0015" clearance between the pump gear and case. My pump was out of tolerance so I replaced it with a newer remanufactured style pump. The trannny shop said that I was picky and the main thing to worry about is the there are sharp edges in the pump housing and the side gear clearance wasn't as much of an issue. But I want to make sure the pressures are where they should be.

New pump installed

Exploded view of the valve body. I put a stage three shift kit in. They say cleanliness and staying organized is the main thing to worry about here. DO NOT WISE DOWN WITH RAGS OR PAPER TOWELS. The valves have very tight tolerance and can easily get hung up by a piece off lint or debris.

Valve body gasket on and ready for the intermediate servo piston and valve body. Again parts organization is a must. The two studs sticking out where the valve body goes are tow 5/16" bolts 2-1/2" long with the heads cut off and slotted for a flat head screw driver. these help line up the gaskets and valve body. The studs are also used when installing the pump assembly.

Valve body installed.

Remember I said keep parts organized? Well after installing the valve body I noticed this washer on the bench. Luckily I remembered it goes between the intermediate servo piston and apply pin. Oops, off with the valve body, install washer, reinstall valve body.

Little trick in knowing if your tork converter is in all the way. With a flat edge across the bolt flange measure to the converter lug flanges. This should be about 1 inch. I replaced my stock converter with a 2600 stall.

Tranny all together

Two 3/8" studs to help line up the tranny for the install.

I also used red high performance clutches. new steels, seals, gaskets, all new bushings, thrust washers and torrington bearings.